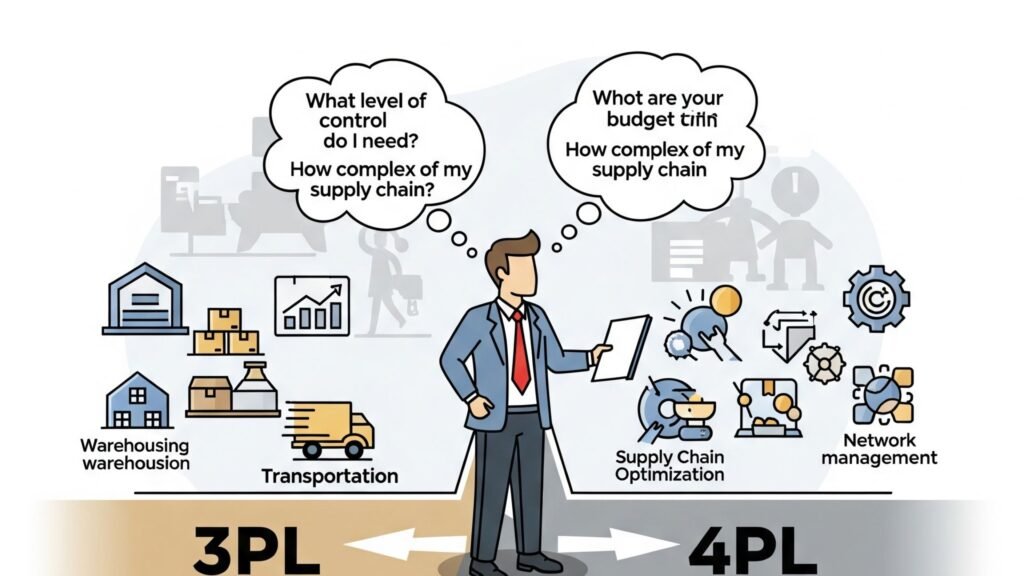

3PL vs 4PL: What’s the Difference & Which One is Right for Your Business

As someone who’s been dabbling in logistics and supply chain strategy for a while now, one question I get asked a lot is: What’s the difference between 3PL and 4PL? And more importantly—which one should you choose?

Let’s break it down in simple terms, explore the pros and cons, and see where each fits in your logistics puzzle.

First Things First: What Do 3PL and 4PL Mean?

What is 3PL (Third-Party Logistics)?

3PL stands for Third-Party Logistics. In short, it means outsourcing your logistics operations—like warehousing, inventory, order fulfillment, and shipping—to a specialized provider.

Think of 3PL as your logistics partner that takes over a part of the supply chain so you can focus on growing your business.

Example: If you’re an eCommerce brand, a 3PL provider stores your products, packs them when orders come in, and ships them to your customers.

What is 4PL (Fourth-Party Logistics)?

4PL, or Fourth-Party Logistics, is a bit more advanced. A 4PL provider doesn’t just handle your logistics—they manage your entire supply chain from end to end.

You can think of them as a logistics consultant or manager. They coordinate with multiple 3PLs, carriers, warehouses, and tech systems, acting as your single point of contact.

Example: A 4PL provider might design and oversee your whole supply chain network, monitor performance, manage multiple vendors, and use data to improve efficiency.

The Advantages of 3PL

- Scalability and Flexibility

- You can scale operations up or down based on demand without investing in your own infrastructure.

- Cost Savings

- Shared warehousing and transport networks lower costs, especially for small and mid-sized businesses.

- Expertise and Efficiency

- You benefit from a team of logistics experts without building one in-house.

- Focus on Core Business

- You get more time to focus on marketing, product development, or customer service.

The Downsides of 3PL

- Less Control

- Once outsourced, you may have limited control over how logistics operations are handled.

- Integration Challenges

- Syncing systems and data between your business and a 3PL can be a bit messy.

- Hidden Costs

- Fees for storage, packaging, or returns might add up if not clearly defined in the contract.

The Advantages of 4PL

- Complete Supply Chain Management

- A 4PL acts like a logistics architect—they design, implement, and manage your entire logistics ecosystem.

- Single Point of Contact

- You don’t need to deal with multiple vendors. One partner takes care of it all.

- Data-Driven Decisions

- Many 4PLs offer high-level analytics and reporting, helping you make strategic decisions.

- Improved Efficiency

- They can streamline operations by eliminating redundancies and optimizing routes and warehouses.

The Downsides of 4PL

- Higher Costs

- Because of their comprehensive service, 4PLs often charge a premium.

- Dependency

- You might become overly reliant on the 4PL, making it hard to switch or bring operations back in-house.

- Not Ideal for Small Businesses

- If you’re a startup or small business, a 4PL might be overkill and financially unsustainable.

So… 3PL or 4PL – Which One Is Right for You?

Here’s my take:

- Go with 3PL if you’re a growing business that needs help with warehousing, shipping, and order fulfillment—but still wants control over strategy and decision-making.

- Consider 4PL if your operations are complex, you’re working with multiple vendors, and you want a strategic partner to optimize your full supply chain.

Both 3PL and 4PL can be game-changers—it just depends on what stage your business is in and how much control you’re ready to let go of.

Final Thoughts

Logistics isn’t just about moving stuff from Point A to Point B anymore—it’s about speed, efficiency, and customer satisfaction. Whether you choose 3PL or 4PL, make sure your provider aligns with your goals, communicates well, and scales with you as you grow.

Been there, done that—and trust me, the right logistics partner can make or break your business.